Current Projects:

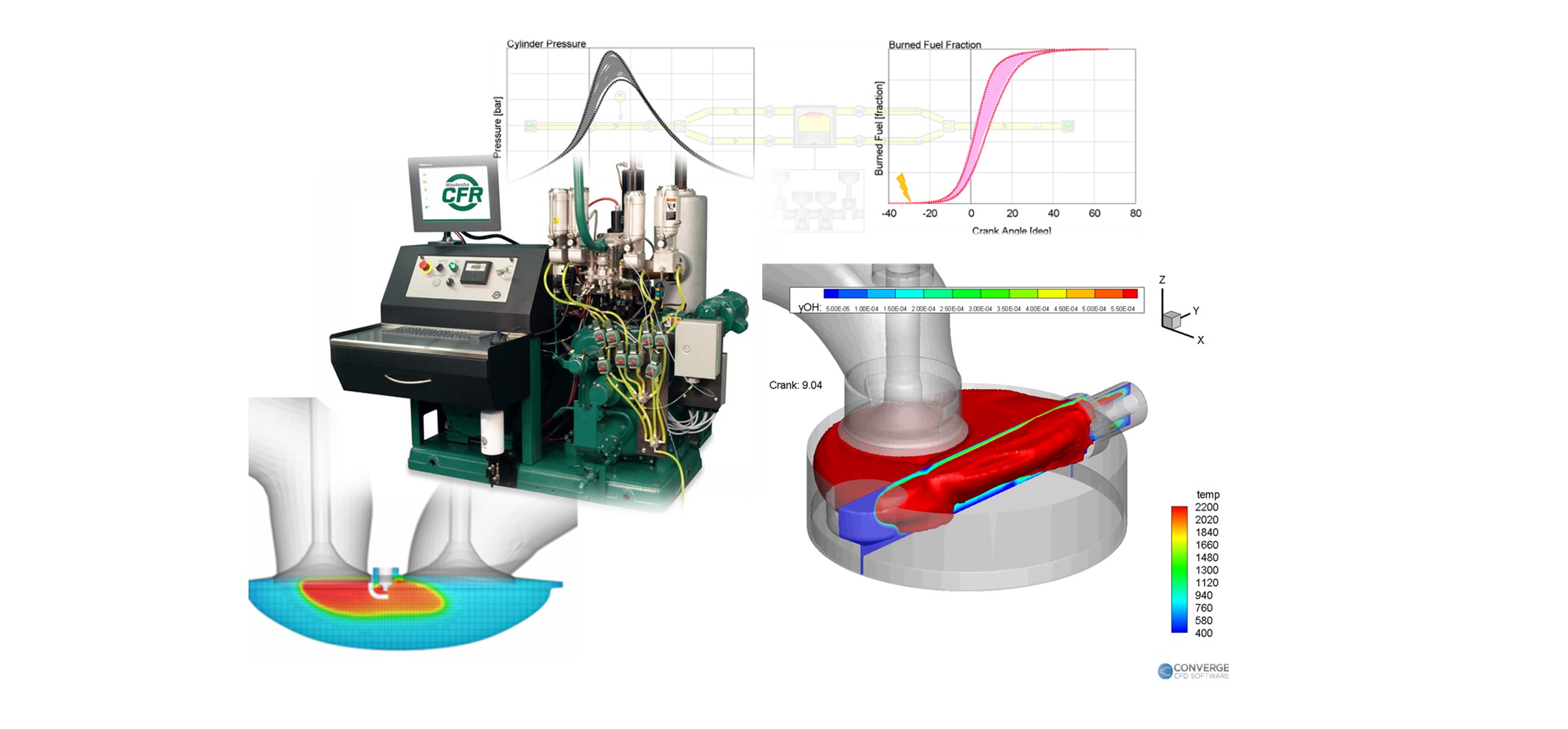

I. 3-D Modeling of the CFR Engine Toward the Development of a High Efficiency Controlled End Gas Auto-ignition Natural Gas Engine

This work is part of a project where an on-road Natural Gas (NG) Spark-Ignited (SI) engine has been under development to achieve Diesel-like efficiencies. Engine knock and misfire are barriers to pathways leading to high-efficiency NG engines. The general tendency to knock is highly dependent on engine operating conditions and the fuel reactivity. The problem is further complicated by low emission limits and the wide range of chemical reactivity in pipeline quality NG (65< MN<95). In order to realize diesel-like efficiencies, spark-ignited NG engines must be designed to operate at high BMEP near knock limits over a wide range of fuel reactivity. This requires a deep understanding of combustion-engine interactions significant in flame propagation and end-gas autoignition. This work aims to develop a three-dimensional computational fluid dynamics (CFD) model of the Cooperative Fuel Research (CFR) engine to investigate knock behavior with NG. The CFR engine model is used to investigate fuel-engine interactions that lead to knock with NG, including effects of fuel reactivity, engine operating parameters, and exhaust gas recirculation (EGR).

3-D Modeling of the CFR Engine for the Investigation of Knock on Natural Gas

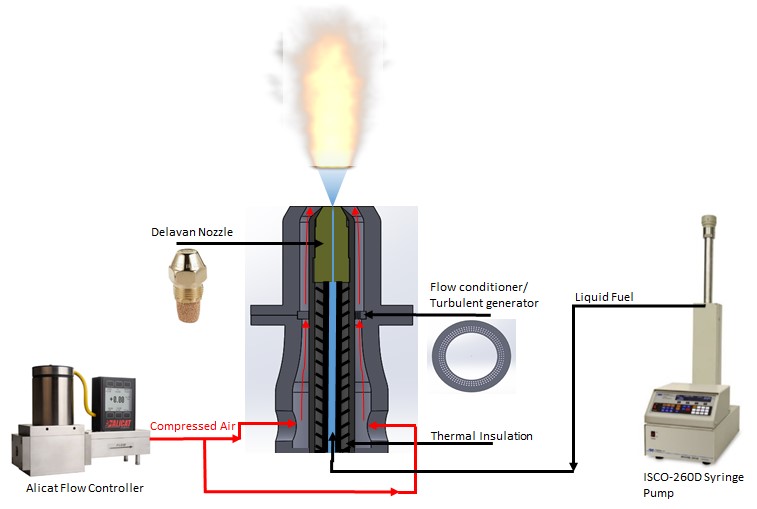

II. The Role of Spray Processes and the Physical and Chemical Properties of Single and Multicomponent Liquid Fuels on Flame Stability and Behavior

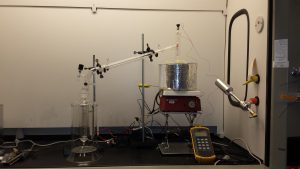

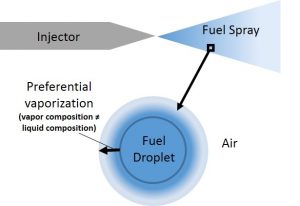

This project aims to understand the coupling between the physical and chemical properties of single and multicomponent liquid fuels (e.g., jet fuels) on flame stability. More specifically, we are investigating the role of these properties on the spray process, e.g. atomization and subsequent evaporation processes of multi-component fuels, including preferential vaporization effects, on flame stability and behaviors, and how these phenomenons should be considered in the surrogate fuel formulation activities and model-based design approaches. To achieve these goals, we have designed and built a new spray burner to simulate the environment that liquid fuel goes through in gas turbine engines. The experimental apparatus, which is used for this project, is illustrated in the figure below. The specifications of the Annular Co-Flow Spray Burner (ACF – Spray Burner) are:

- Delivering high air co-flow up to 3000 L/min using flow mass controller (Alicat, MCR-3000SLPM-D-PAR).

- Ability to heat the air co-flow to ~500K.

- Delivering a high liquid fuel flow rate up to 107 mL/min using a syringe pump (ISCO, Model 260D).

- Ability to use different nozzle sizes (different injector diameter sizes) to control the droplet sizes for different fuels.

In collaboration with the United States Air Force Academy, we are investigating the behaviors of surrogate fuels developed to model the behavior of real jet fuels. Due to the complex nature of jet fuels, which will contain hundreds of different hydrocarbon species, researchers have developed surrogate fuels – mixtures of a small number of well-understood compounds such as dodecane, toluene, iso-cetane, and others – which can be used as stand-ins for the more complicated jet fuels in simulation and testing. We study the performance of these surrogates in real spray flames to determine the degree to which they accurately emulate jet fuel in varying conditions, and using various laser diagnostic and imaging techniques, we can identify spray and flame characteristics that affect the fuel performance.

The development of a high power laser-based combustion imaging and the diagnostic facility is underway to study turbulent flame stability and dynamics. The facility will utilize a unique seeded high power YAG laser to carry out a suite of combustion diagnostic techniques, including, Planar Laser Induced Fluorescence (PLIF), Rayleigh Light Scattering/Thermometry, Mie droplet scattering/PIV, Raman spectroscopy, as well as, fundamental laser plasma ignition studies.

Liquid Jet Fuel Property Impacts on Combustion Performance

III. Lubricant dilution with high pressure natural gas and impact on natural gas compressor lubrication

Colorado State University is partnering with the Gas Machinery Research Council to investigate the relation between oil lubricity and the time the oil is exposed to natural gas. Natural gas (composed mostly of methane, ethane, and propane) is oil soluble. As the natural gas components are dissolved into an oil, the viscosity of the oil decreases. This decrease in viscosity can prevent the oil from lubricating a compressor properly. Currently, natural gas compressors are over lubricated to prevent expensive equipment failures. However, this excess oil, entrained with natural gas, must be removed downstream, which can also result in costly system downtime. The goal of this research is to find a relation between oil lubricity and oil-gas exposure time. This relation will then be used to estimate optimal lubricant feed rates for industrial natural gas compressors.

IV. Modeling of Ablative and Regenerative Cooling System for Liquid Fuel Rocket Engine

This project focuses on determining the most effective cooling system for a non-cryogenic bi-propellant liquid-fuel rocket engine. Rocket engines create extreme conditions for any material to withstand; moreover, materials lose integrity well below their melting points, and the temperatures in rocket engines typically surpass the melting points of metals by a substantial quantity. This necessitates an effective cooling system for the rocket engine to be able to endure the required burn durations. Two common cooling systems for rocket engines are ablative and regenerative. Ablative cooling is a process that utilizes a sacrificial liner which cools the engine through chemical reactions and enthalpy of vaporization. The chemical reactions decrease temperatures in the boundary layer, while charring creates an insulating layer on the chamber walls. Regenerative cooling incorporates the flow of pressurized propellants in channels on the exterior surface of the regions of the rocket which experience the highest heat flux, typically the throat and combustion chamber. Flowing liquid through cooling channels along the outside of the engine wall acts as a heat exchanger by absorbing heat. Liquid rockets enable the potential use of the fuel as a coolant; however, liquid fuels have a relatively small temperature gradient before a phase change occurs. Reserving this small gradient for the sections nearest the nozzle allows for the greatest benefit. In collaboration with Pioneer Astronautics, these two cooling methods are being modeled and compared using both analytical and numerical CFD-FEA methods to simulate the fluid dynamics and heat transfer within the rocket engine.

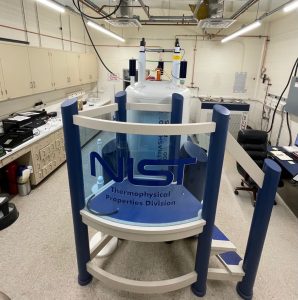

V. Natural Gas -Water Vapor Liquid Equilibrium Measurements Using NMR Spectroscopy

In collaboration with the Gas Machinery Research Council and the National Institute of Standards and Technology, Colorado State University is measuring high pressure vapor-liquid equilibrium of methane and water mixtures to improve natural gas transportation. Natural gas transportation utilizes well-established pipelines and compressors across the United States. In order to maintain compressor lifetime and optimize the efficiency of the entire transportation process, operators utilize equation of state software to determine operating conditions. The high-quality data collected will be implemented into NIST’s REFPROP equation of state software to improve the predictive capabilities for the compressor station operators.

VI. Poly-oxymethylene ethers with extended alkly end groups as an optimized bio-derived diesel fuel blend stock

VII. High Efficiency Direct Injection LPG Engine – LPG Spray Characterization

VIII. High Efficiency Fuel Cell/IC Engine Hybrid Power Generation System: Simulation and Design of High Efficiency Dilute Syngas Fueled Engine

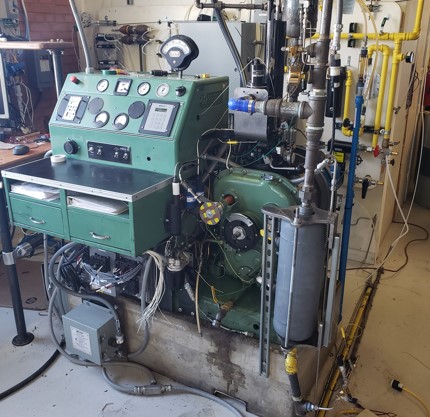

This study deals with the utilization of low heating value mixtures, like dilute hydrogen syngas mixtures, as fuel in conventional IC engine. These kinds of gases are usually used in the synthesis of other products like urea or are produced as products of reactions such as biomass gasification or hydrocarbon reforming. General Syngas is mostly composed of hydrogen and carbon monoxide with varying levels of dilution by many other gases such as carbon dioxide or water. The goal of the current project is to develop a virtual combustion model of the CFR engine using such dilute low LHV fuels. The model should be able to predict the performance of the engine and also operating conditions that can cause knock in the engine when using the dilute syngas. CAE software, GT-Power, and Chemkin are being used to develop the combustion model. The tasks involved in this project include gathering experimental data from the CFR engine while running on the dilute syngas mixture, selection of a chemical mechanism suitable to model the syngas combustion, using the Three Pressure Analysis (TPA) on the model using the experimental data and then finally optimizing the combustion model to allow for predictive results. The long term goal of the project is to replicate the predictability of engine performance and operating envelope for different IC engines.

Modelling and simulation of combustion of dilute syngas fuels in a CFR engine

Past Projects:

I. Computational Fluid Dynamics of Automotive Refueling Systems

Working with partners at Honda R&D, we are developing CFD models capable of predicting the complex multi-phase fluid dynamics required to design low hydrocarbon vapor emitting/high-performance automotive refueling systems. Model development is coupled with experimental validation to ensure that the simulations can accurately capture the flow through the nozzle and the output spray leading to the turbulent flow through the filler pipe and the phase change and hydrocarbon vapor flow within the fuel tank and the onboard refueling vapor recovery system (ORVR).

Computer aided engineering of an automobile gasoline refueling system

II. Computational Fluid Dynamics of a JP-8 Fueled Unmanned Aerial Vehicle

The US military is beginning to recognize the benefits of a Single-Fuel Policy, as several studies have been conducted to analyze the feasibility. Heavy Hydrocarbon fuels are of interest to the military as a prime candidate for the single fuel policy. However, since JP-8 is less volatile and has short ignition delays, it is more prone to cause engine knock during combustion. Stratified combustion is being used to reduce the probability of engine knock by promoting conventional combustion propagation from the point of ignition (spark plug) down to the piston. Stratified combustion is achievable by modifying the fuel injector properties to change the injection rate shape. Rate Shape is a plot of mass over time of the fuel as it comes into the cylinder of the engine. Due to the unique characteristics of JP-8, extensive research must be conducted to find the best parameters for proper ignition in gasoline engines through the manipulation of fuel injection.

III. Fuel Volatility and Distillation Dependent Property Measurement

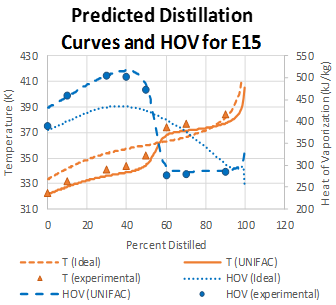

The volatility or phase change behavior of fuels is being measured using the Advanced Distillation Curve (ADC) apparatus (top right) and method developed at NIST.1 The distillation curve is a highly important fuel property to determine engine compatibility and is an important metric to derive simple fuel surrogates. The ADC method provides true thermodynamic state points which allow for equation of state modeling and has a unique sampling feature which when coupled with appropriate chemical analyses (e.g. GC-MS/FID and Windom_CV_2017) can provide the composition of the distillate fractions, allowing for evaluation of relevant fuel properties as the fluid evaporates (including e.g., HOV and Hcomb).

IV. Counter-flow Flame Studies – Effect of Endothermic Reactions in Regenerative Cooling Applications

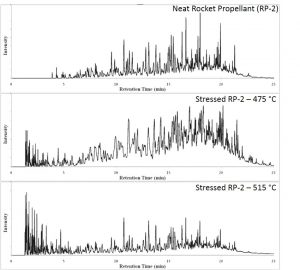

Work is being carried out to measure flame properties of real fuels using a counter-flow flame burner. The counter-flow flame provides an excellent platform to study the combustion behaviors of fuels as it can be estimated as one dimensional (along the z-axis) such that the physics can be modeled and compared to the experiment. This provides a tool to validate kinetic mechanism and transport properties of fuels. By coupling a high pressure reactor to the counter-flow flame burner, the affect of endothermic reactions on the subsequent combustion of jet fuels is being investigated. In particular diffusion flame extinction strain rates between the un-reacted fuel and the thermally stressed fuel are being measured and compared to show how the regenerative cooling process can alter flame dynamics/stability.

Effect of endothermic reactions on the global extinction strain rate of large hydrocarbon fuels

V. Fuel Evaporation – Impact on Combustion and Particulate Matter Emissions

Using distillation curve measurements as the basis, a fuel droplet evaporation model of multi-component petroleum/biofuel blended fuels has been developed to show the impact of high heat of vaporization and non-ideal (azeotropic) interactions, which are characteristic of biofuels, on fuel droplet life times and composition. Recently, trends predicted by the model have been used to explain elevated PM emissions observed by colleagues at NREL’s ReFuel Lab for high ethanol concentrated gasoline fuels in direct injection spark ignition engine (DISI). Please find our recent paper for more information.